The idea that materials could repair themselves may once have belonged solely to the realm of science fiction, but in recent years, it has moved firmly into the territory of scientific reality. Self-healing materials—substances engineered to automatically repair damage—are no longer speculative concepts; they are being developed in labs, tested in real-world scenarios, and increasingly integrated into product design. In the context of electronics, where durability, performance, and sustainability are always under pressure, self-healing materials might not just be a technological novelty—they could represent a transformative shift in how devices are built, used, and maintained.

At the heart of this development is a basic yet powerful premise: electronic devices often fail not because of complex circuitry malfunctions, but due to small, cumulative damage. Whether it’s a cracked phone screen, a severed internal wire, or moisture degrading circuit boards, wear and tear is inevitable. What self-healing materials offer is a way to extend the usable life of devices by allowing them to recover from such damage—sometimes within seconds, and often without user intervention. That prospect alone is enough to spark interest from manufacturers, investors, and consumers alike.

From a business standpoint, the implications are compelling. Consider smartphones, which are notorious for their fragility despite advances in screen materials and casing design. A phone screen embedded with a polymer that responds to heat or pressure by closing cracks could dramatically reduce the need for costly repairs or replacements. For manufacturers, that translates into fewer warranty claims and improved customer satisfaction. For consumers, it means fewer trips to the repair shop and less anxiety over accidental drops. The ripple effect could reach insurance companies as well, potentially shifting coverage models as the frequency of claims diminishes.

But the potential stretches far beyond phones. In wearable technology, where devices are subject to constant movement and exposure to elements, flexibility and resilience are essential. Self-healing materials can address both. Researchers are experimenting with conductive inks that reestablish electrical pathways after being stretched or torn, allowing wearables to maintain performance even under stress. This could lead to more reliable fitness trackers, medical monitoring systems, or even e-textiles—clothing that houses embedded electronics without sacrificing comfort or longevity.

The automotive and aerospace industries are also exploring these materials, particularly for use in sensors and circuits embedded in structural components. A self-healing sensor array in an aircraft wing, for example, could continue functioning even after experiencing microfractures, providing engineers with real-time diagnostics and increasing safety margins. Similarly, in electric vehicles, where battery performance and system integrity are paramount, materials that detect and respond to internal faults could mitigate risks before they escalate into critical failures.

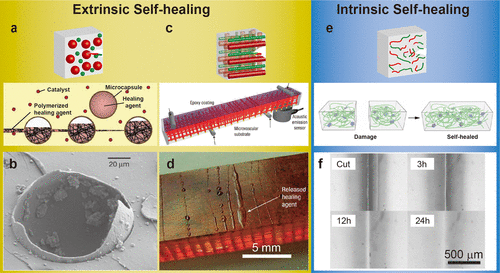

For all their promise, self-healing materials still face several hurdles before widespread adoption becomes reality. The technology must be cost-effective, scalable, and compatible with existing manufacturing processes. While some materials work by releasing microencapsulated healing agents when damaged—much like biological systems—others rely on reversible chemical bonds that can reform after being broken. Each approach has trade-offs. Some systems are limited to healing once, while others can restore themselves repeatedly. Additionally, maintaining performance, particularly for conductive materials that must carry electricity efficiently, remains a key challenge.

There’s also the matter of user expectations. While consumers might welcome a self-healing screen that smooths out scratches, they will be less forgiving if the repair process leaves visible distortions or slows device response times. Therefore, refining not only the function but also the aesthetics and seamlessness of the healing process is crucial to consumer acceptance.

Another important layer in this conversation is sustainability. As the tech industry grapples with growing e-waste and the environmental impact of rapid product cycles, self-healing materials offer a chance to reduce the frequency of device disposal. Extending the functional life of electronics aligns with circular economy principles, which prioritize reuse, repair, and recycling over disposal. For companies facing regulatory pressure and environmentally conscious markets, integrating self-healing components could serve both ecological and branding purposes.

Looking ahead, the integration of artificial intelligence and machine learning with self-healing systems could take things even further. Imagine a device that not only repairs itself but learns from the type and frequency of damage to predict and prevent future issues. This predictive maintenance model, already common in industrial machinery, could find its way into consumer tech, making our devices not just more durable but smarter and more adaptive over time.

As research continues and commercial applications expand, it’s becoming increasingly difficult to dismiss self-healing materials as a niche pursuit. Their relevance is growing in parallel with our dependence on electronics in nearly every aspect of life and work. While we are still in the early stages of integrating these materials into mass-market products, the trajectory is clear. What began as an academic curiosity is evolving into a practical solution with the potential to reshape expectations around technology durability.

Are self-healing materials the future of electronics? It’s unlikely they will completely redefine the industry overnight. But as the demand for more resilient, longer-lasting, and environmentally responsible devices rises, these materials are positioned to become a crucial component of tomorrow’s technology. Their ability to quietly solve problems before they escalate could mark a turning point—not just in how we use our devices, but in how we think about the relationship between technology and longevity. In a world where electronics are increasingly vital and deeply personal, that shift couldn’t come at a better time.